Differential Pressure Leak Tester

-

WF-Fifth Generation Detector

The fourth generation of Washington Brothers direct pressure air tightness tester adopts high-precision direct pressure detection technology, which can quickly complete air tightness, IPX waterproof level and leakage detection, with a detection accuracy of ±1Pa. This equipment is widely used in high-end manufacturing fields such as automobiles (engine/air conditioning system detection), aerospace (aircraft component sealing test), consumer electronics (mobile phone/tablet waterproof test), and medical devices (syringe/airbag sealing verification). It can complete non-destructive testing in 3-5 seconds, and the test data is traceable. It is an ideal solution to improve product quality control efficiency.

contact us

| Product Advantages | |

|---|---|

| Parameter Setting | This device can be set with different detection parameters according to product requirements, making it suitable for multiple products. |

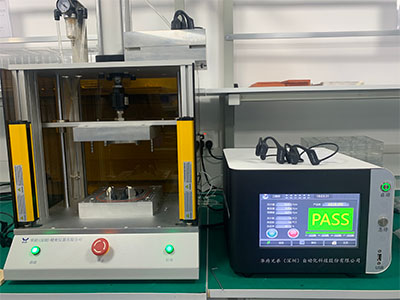

| Testing Function | It has a one-button automatic detection function, which can automatically evaluate whether the test is合格 (green light for合格, red light with alarm for不合格). |

| Signal Input/Output Interfaces | Equipped with multiple signal input and output interfaces, including communication interfaces (connectable to computers, barcode scanners, external control switches), facilitating external control without frequent device operation. |

| Testing Record Storage | Can connect to computers and barcode scanners; product test records will automatically generate a folder on the computer, facilitating data management and quality tracking. |

| Touchscreen | Features a 7-inch Weizen LCD touchscreen, with a user interface customizable according to customer requirements. |

| Core Components | All core components come from professional brands in Japan, Germany, and Taiwan, ensuring detection accuracy and device stability. |

| Communication Interfaces | Multiple communication interfaces: built-in RS232 serial port, RJ45 network port, USB communication interface, etc. |

| Pressure Range | Provides multiple range options; pressure range: -80 KPa to +2000 KPa. A super-high pressure electromagnetic valve patent has been applied for, ensuring no leakage in ultra-high pressure conditions. |

| Resolution | Uses 24-bit AD analog-to-digital conversion technology, with detection sensitivity reaching 0.02 Pa. |

| Basic Parameters | Product dimensions: 400x330x200 (mm), product weight: approximately 14 kg, power supply: AC220V, 50/60 Hz. |

| Product Parameters | |

|---|---|

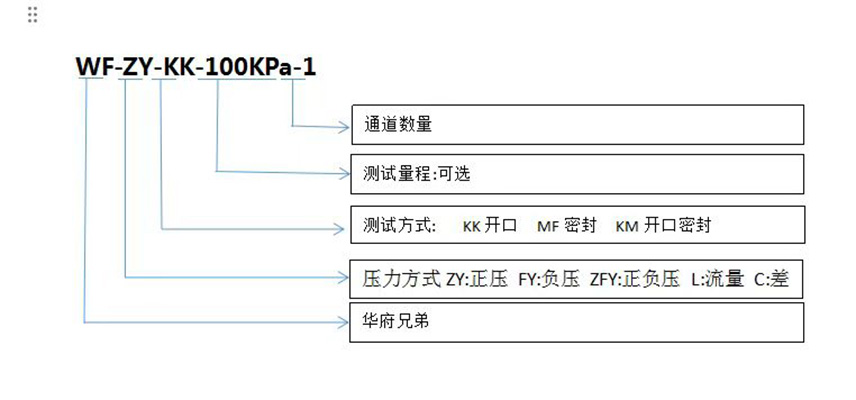

| Number of Channels: | 1/2/4 |

| Pressure Type: | Positive pressure, negative pressure, positive/negative pressure |

| Pressure Adjustment Mode: | Manual adjustment/Auto adjustment |

| Pressure Adjustment Precision: | ± 0.05%FS |

| Pressure Repeatability: | 0.1%FS |

| Pressure Adjustment Range: | -95 KPa – +3000 KPa |

| Sensor Selection Range: | -95 KPa – +3000 KPa |

| Sensor Precision: | 0.1%FS |

| Resolution: | 0.1 Pa |

| Function Introduction | |

|---|---|

| Touchscreen: | 7/10-inch color LCD |

| Operating Interface: | WAFU UI |

| Languages: | Chinese, English, Japanese, German, Spanish, Russian (other languages can be customized) |

| Number of Programs: | 16/99 groups of programs |

| Judgment/Alarm: | Automatic judgment/Audio and visual alarm |

| Control I/O Ports: | Input/Output, 4 relay control functions (connectable to safety barriers, electromagnetic valves, and red/green warning lights) |

| Serial Communication (RS485): | Receives external PLC control signals, connects to workstations |

| USB: | Software updates, barcode scanner |

| Barcode Scanning: | Barcode |

| Historical Records: | Can store 100,000 test results and upload them to a computer using a USB flash drive. |

Product Advantages

One, Widespread Application Fields

Two, Multiple Testing Methods

Three, Industry Certification Certificates

Four, Up to Eight-Channel Detection