Industry experience

WaFu Brothers - Sixteen years of hard work to create an industry benchmark

WaFu Brothers (Shenzhen) Automation Technology Co., Ltd.Founded in 2009, with 16 years of experience in the production of airtightness testers and non-standard automation equipment, it is one of the first manufacturers of airtightness and waterproofing testers in China, serving more than 8,000 customers at home and abroad, including Audi.

We regard product quality as our life. We strictly follow the ISO9001 quality management system in every production link of leak detectors. We regard product innovation as our blood and attach great importance to R&D investment. Over the years, the annual R&D investment in leak detection technology has accounted for more than 20% of sales.

For 16 years, we have been forging ahead, and the spirit of striving for the first place has become the belief engraved in the bones of all WaFu Brothers employees. The flowers that we have watered with sweat day and night for many years have finally borne fruit. We are the first to completely solve the industry's major problem of sealing testers - environmental interference affects the detection accuracy!

Products

Multi-channel leak tester

WF sixth-generation multi-channel leak tester - WaFu Brothers' 15-year-long ingenuity to create an efficient airtightness testing solution, supports differential pressure, flow, direct pressure and other testing methods...

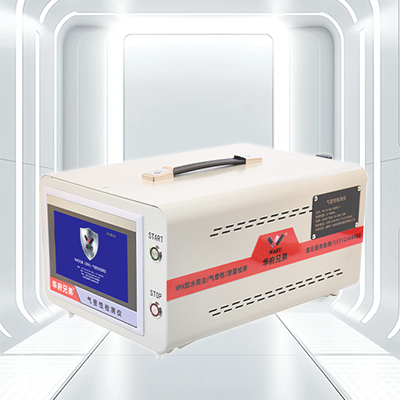

HF-Flow detector

HF series sixth generation air tightness tester - with high-precision flow sensor as the core, it adopts instantaneous flow loss algorithm to directly measure air permeability, leakage rate and...

Cabinet air tightness test

The cabinet-type leak tester is the "all-around guard" of automobile engine cover inspection. It can automatically detect whether the screw collar is missing, and can also accurately test the sealing of the entire engine cover, strictly guard the protection level, and has

Industry application

Why choose WaFu Brothers

Since its establishment in 2009, WaFu Brothers has started to develop air tightness testers based on the most advanced foreign technology and has accumulated rich industry solution experience!

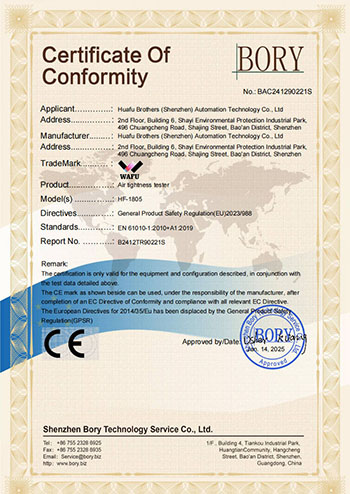

Authoritative certification

The accuracy is as high as

satisfied customers

Industry information

-

Why is Leak Testing Necessary for Juicers?

As kitchen appliances, juicers often operate in humid and water-splashing environments. Inadequate sealing performance may lead to...

-

The Importance of Leak Testing for Engine Hood Assemblies

The engine hood assembly is not only part of a vehicle's exterior structure but also serves critical functions such as sealing, dustproofing, waterproofing, heat insulation, and noise reduction. Poor sealing during manufacturing can lead to the following issues...

latest

Hot Topics

All-in-One Leak Testing Solutions|WAFU Brothers Empowers Manufacturing with Zero-Leakage Vision

In the world of precision manufacturing, an invisible "seal line" determines product safety, durability, and quality. Whether it’s battery packs for new energy vehicles or wearable electronics requiring IP protection, any leakage or seal failure can lead to product scrap and brand reputation damage.

WAFU Brothers, with 16 years of expertise in airtightness testing, is committed to providing efficient, precise, and traceable leak testing equipment and airtightness testing devices tailored to your industry needs.

Multiple Detection Methods for Diverse Industry Needs

| Testing Type | Product | Application | Main Advantages |

|---|---|---|---|

| IP Rating Test | Waterproof Testing Instrument | IP67/IP68 testing (3C electronics, outdoor devices) | Simulates water pressure, non-destructive, high precision |

| Leak Flow Monitoring | Flow-type Airtightness Tester | Radar modules, complex electronic structures | Visual leak flow display, automatic judgment |

| Pressure Decay Measurement | Differential Pressure Leak Tester | EV battery packs, control enclosures, micro-cavities | ±0.1 Pa precision, excellent repeatability |

| General Sealing Check | Direct Pressure Leak Tester | Medical consumables, small appliances | Fast testing, easy operation, cost-effective |

Why Choose WAFU Brothers?

- 📌 16+ years of expertise: In-house algorithms, trusted by 3,000+ clients

- 📌 Turnkey customization: From fixture design to full production line integration

- 📌 Data traceability: MES-compatible, full leak data record and analytics

- 📌 Global standards: CE certified, widely used by overseas manufacturers

Success Cases

| Industry | Product | Test Method | Outcome |

|---|---|---|---|

| Consumer Electronics | Bluetooth Earbud Shell | Waterproof + Differential Pressure Testing | Supports IP68, 30,000+ pcs/day tested |

| Medical Devices | Infusion Set / Catheter | Direct Pressure Leak Tester | <3s test cycle, passed EU standards |

| EV Batteries | Battery Shell Airtightness | Differential Pressure Testing | Stability within ±0.3 Pa |

Wide Applications Across Industries

Our airtightness testing instruments and leak detection solutions are widely applied in:

- New Energy: PACK modules, battery covers, cooling housings

- Medical: Pressure cuffs, oxygen masks, disposable syringes

- Automotive Electronics: ECUs, in-vehicle cameras, radar modules

- Smart Devices: Wearables, Bluetooth speakers, electric shavers

Contact HAFU Brothers today and get your exclusive airtightness testing solution!

waterproof testing instrument, airtightness tester, leak detection equipment, seal integrity tester, differential pressure tester, direct pressure leak tester, flow-type air leak detector