Five-Minute Guide: How Leak Testers Work and Key Selection Criteria

Today, Wafu Brothers conducted professional training on air tightness testers. General Manager Deng explained the principles, operation methods, and our standard testing parameters.

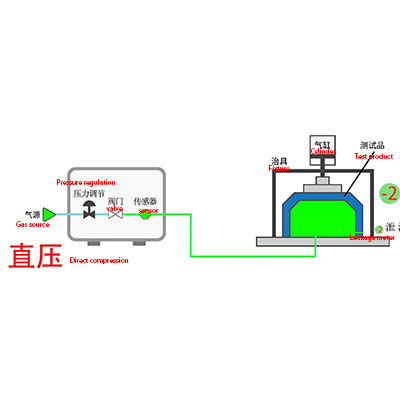

First, General Manager Deng emphasized the fundamental principles and specific working methods of leak testers. The leak testing instruments we use can be categorized into three main types based on their principles: direct pressure method, differential pressure method, and flow method, each with its unique detection logic and advantages.

Positive pressure and

negative pressure are two different scenarios. Positive pressure

operates similarly to "blowing air" into the test object—by injecting a certain

pressure of gas and observing the corresponding pressure changes to determine its

airtightness. Negative pressure, on the other hand, is like "sucking air" out of the

test object, also relying on pressure changes to identify leaks or airtightness

issues. This direct pressure method, which monitors pressure variations, is widely

used in conventional product airtightness testing due to its intuitive operation and

straightforward results.

Positive pressure and

negative pressure are two different scenarios. Positive pressure

operates similarly to "blowing air" into the test object—by injecting a certain

pressure of gas and observing the corresponding pressure changes to determine its

airtightness. Negative pressure, on the other hand, is like "sucking air" out of the

test object, also relying on pressure changes to identify leaks or airtightness

issues. This direct pressure method, which monitors pressure variations, is widely

used in conventional product airtightness testing due to its intuitive operation and

straightforward results.

Next, General Manager Deng discussed the differential pressure method. The principle of this method can be likened to using a balance scale. During operation, a confirmed qualified sample is compared with the test sample under identical conditions. The pressure difference between them is measured—if it falls within the acceptable range, the test sample is deemed qualified; otherwise, it is rejected. The differential pressure method is highly valued for its precision in comparative testing, making it essential in production scenarios requiring strict airtightness standards and consistent product quality.

As for the flow method, it is primarily applied to valves and pipeline products. The airtightness of such products largely depends on whether the fluid flow rate meets the specified standards. The flow method precisely measures the fluid flow rate inside the pipeline and compares it with industry standards or predefined acceptable parameters to determine the product's airtightness. This method plays a vital role in ensuring the sealing performance and safety of valves and pipelines in practical applications.

Finally, General Manager Deng comprehensively outlined the applications of our leak testing instruments across various industries. Different industries have vastly different requirements for product airtightness. For example, in automotive manufacturing, the airtightness of critical components like engines and braking systems directly impacts vehicle performance and safety. In the electronics industry, the sealing performance of devices such as smartphones and tablets affects their waterproofing, dust resistance, and internal component stability. General Manager Deng detailed how our testing instruments adapt to these diverse industry needs.

Additionally, General Manager Deng delved into the testing standard parameters for leak testers. These parameters include pressure range, flow range, allowable error values, and other critical metrics—all derived from extensive experimental validation and industry practice. Strict adherence to these standards ensures accurate and reliable test results, safeguarding product quality.

Furthermore, General Manager Deng addressed common issues encountered when using leak testers, such as the impact of environmental temperature and humidity on results, periodic calibration for long-term use, and potential misjudgments during testing for different product types. He also provided practical solutions and preventive measures for these common problems, helping us operate the equipment more efficiently and ensuring smooth testing processes with reliable outcomes.

Through General Manager Deng's detailed explanation, we gained not only a clear understanding of the principles and working methods of leak testers but also comprehensive knowledge of their industry applications, testing standards, and operational considerations. This has laid a solid foundation for us to better utilize this equipment in future work.

Landline: 0755-2726-7551

Customer Service (WhatsApp): +86 17376311087

Email: wafubrother@outlook.com

Recommended Products