The leak tester provided by WaFu Brothers Company, combined with advanced pipeline airtightness detection technology, can accurately test the sealing performance of pipelines and identify gas leakage issues. Whether it's pressure leak detection or pipeline sealing tests, the company's equipment ensures the safety of pipelines under high-pressure conditions. Utilizing non-destructive testing (NDT) technology, it assesses pipeline sealing in real time while offering an automated leak testing system to enhance testing efficiency, reduce accident risks, and ensure the long-term stable operation of pipeline systems.

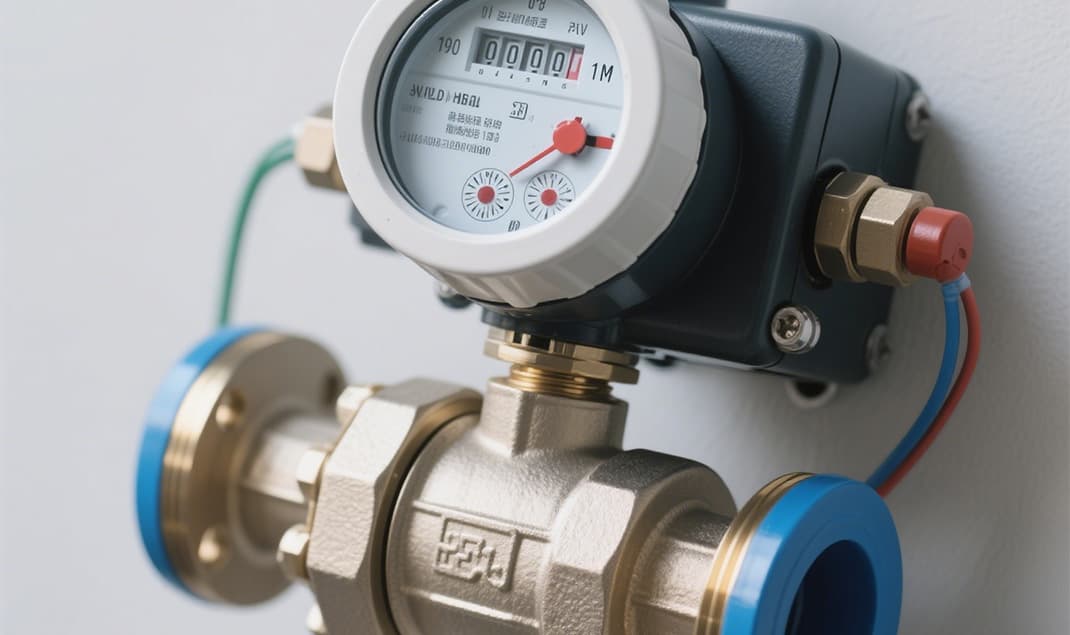

Integrated Control Valve Water Meter

In 2023, a smart water meter manufacturer in Jiangsu needed to meet IP68 waterproof standards for "underground meter chambers" in southern China's water immersion environments. However, they failed third-party testing twice due to O-ring assembly deviations causing water seepage. After implementing high-precision leak testers (combining differential pressure and flow methods) for every unit's final inspection - with independent testing for valve bodies, control compartments, and water ports - their pass rate improved to 99.7%, enabling successful bulk bidding.

More