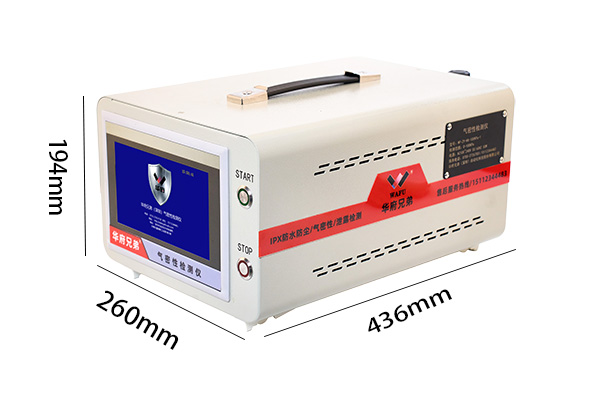

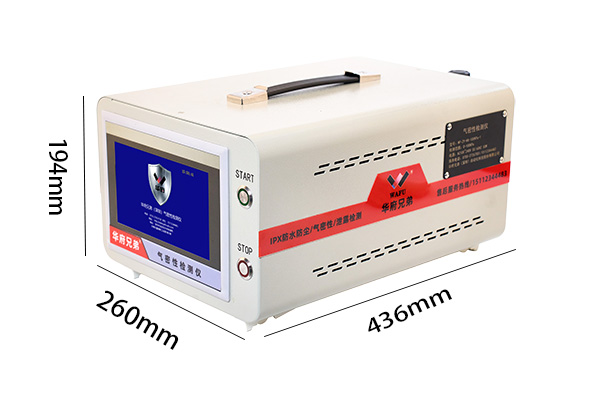

HF-Flow detector

-

HF series sixth generation air tightness tester - with high-precision flow sensor as the core, it adopts instantaneous flow loss algorithm to directly measure air permeability, leakage rate and air leakage value without relying on test volume or leakage rate conversion. It is specially designed for IPX4-IPX6 waterproof test and workpiece flowability detection, suitable for rapid and accurate detection of products such as infusion tubes, capillary copper tubes, waterproof breathable membranes, etc., helping to improve both production efficiency and quality!

HF Series-Sixth Generation

Contact us

Product Parameters

| Technical Parameters | |

|---|---|

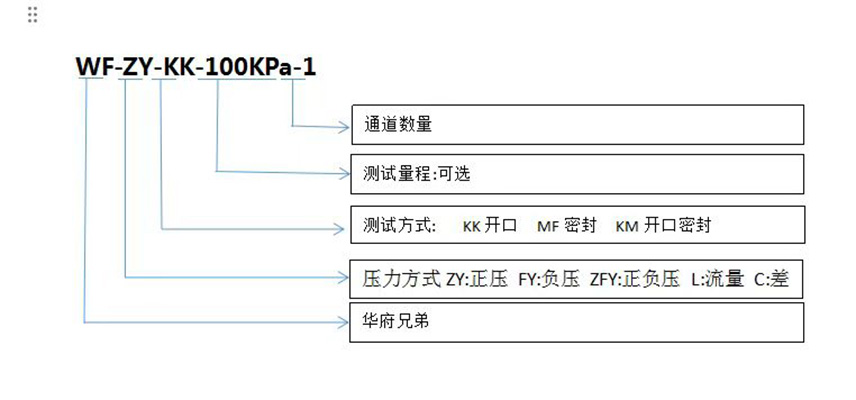

| Number of Channels: | 1 |

| Pressure Type: | Positive pressure, negative pressure, positive/negative pressure |

| Pressure Adjustment Mode: | Manual adjustment/Auto adjustment |

| Pressure Adjustment Precision: | ± 0.05%FS |

| Pressure Repeatability: | 0.1%FS |

| Pressure Adjustment Range: | -95 KPa – +3000 KPa |

| Sensor Selection Range: | -95 KPa – +3000 KPa |

| Sensor Precision: | 0.1%FS |

| Resolution: | 0.1 Pa |

| Function Introduction | |

|---|---|

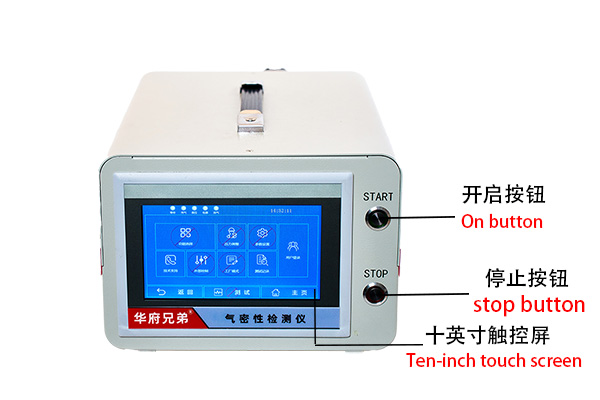

| Touchscreen: | 7-inch color LCD |

| Operating Interface: | WAFU UI |

| Languages: | Chinese, English, Japanese, German, Spanish, Russian (other languages can be customized) |

| Number of Programs: | 16/99 groups of programs |

| Judgment/Alarm: | Automatic judgment/Audio and visual alarm |

| Control I/O Ports: | Input/Output, 4 relay control functions (connectable to safety barriers, electromagnetic valves, and red/green warning lights) |

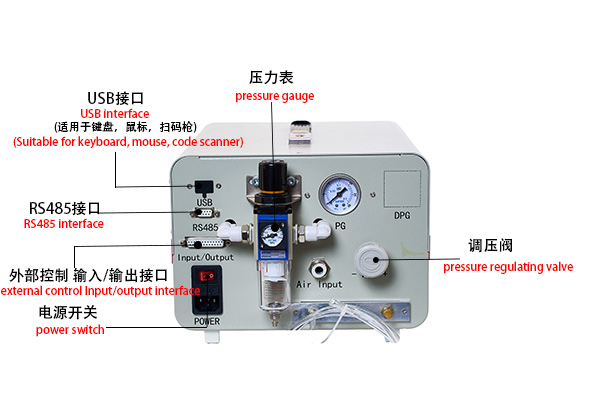

| Serial Communication (RS485): | Receives external PLC control signals, connects to workstations |

| USB: | Software updates, barcode scanner |

| Barcode Scanning: | Barcode |

| Historical Records: | Can store 100,000 test results and upload them to a computer using a USB flash drive. |

Detail Display

User Interface UI

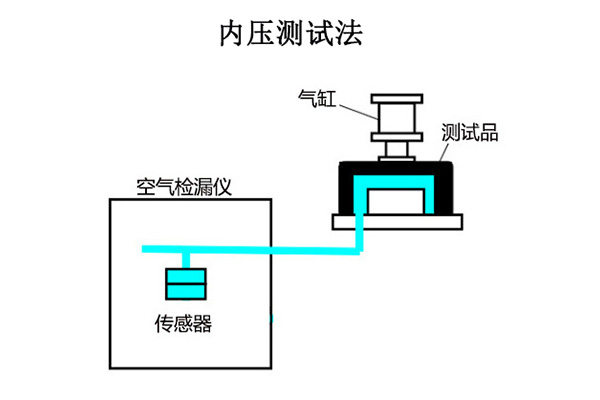

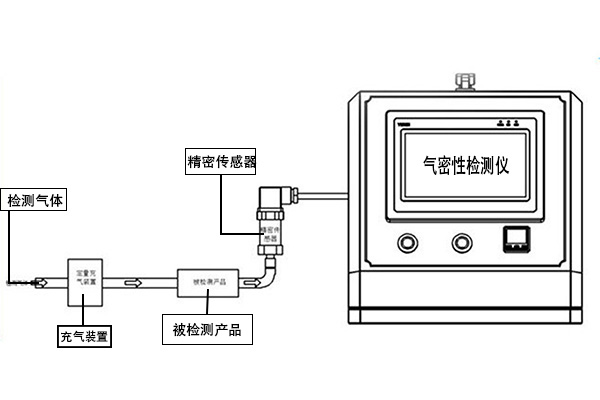

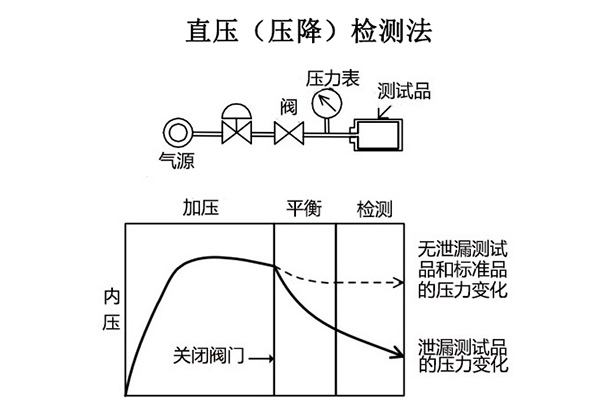

Testing Methods

Product Advantages

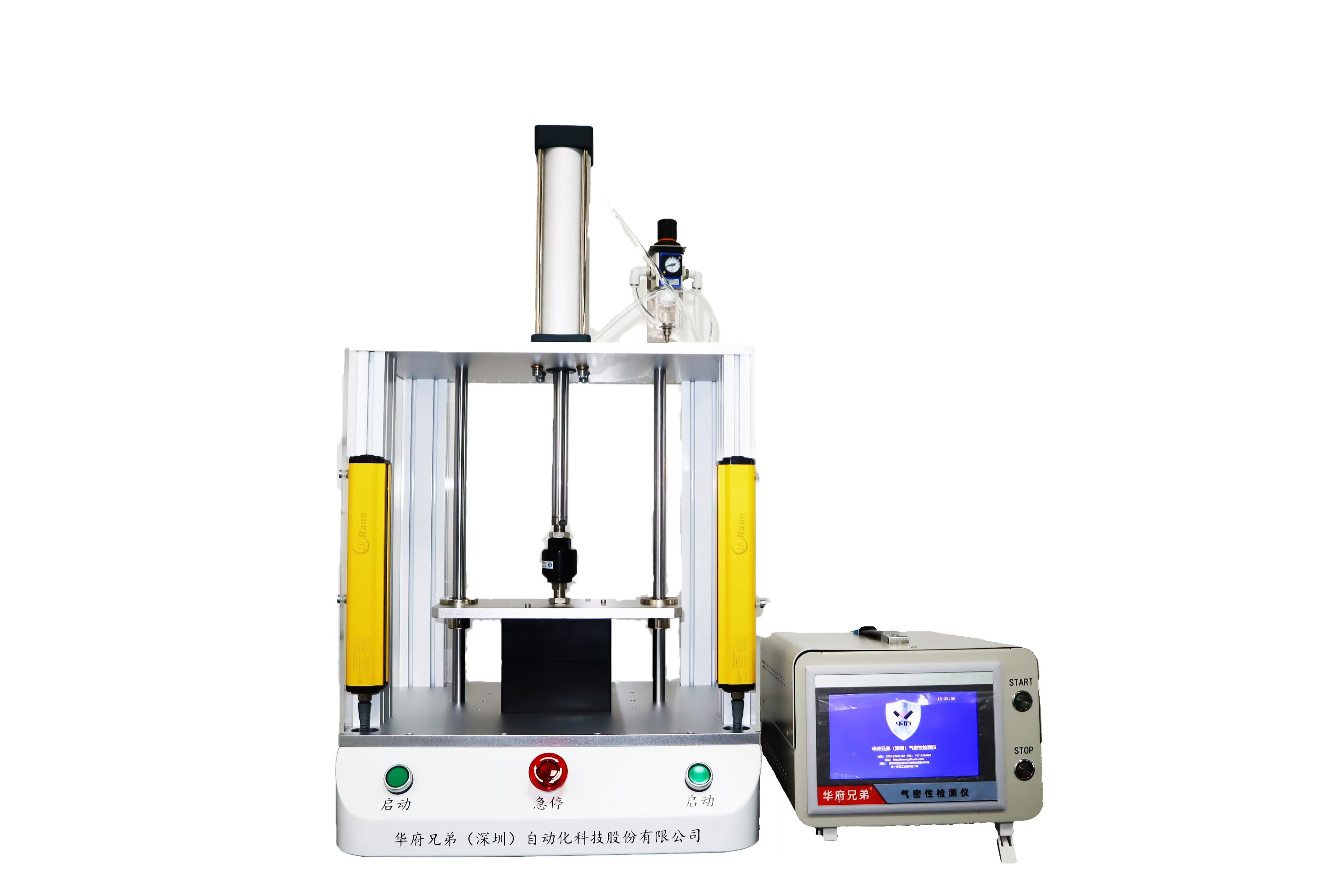

One, Comfortable Size

Two, Multiple Testing Methods

Three, Multiple Patents

Four, Widespread Application Fields