WaFu Brothers plays a key role in the field of leak testing in the aerospace industry, providing high-precision testing equipment. Its technology is used for spacecraft cabin sealing testing to ensure that the cabin is leak-free; for fuel system testing to ensure the safety of fuel tanks and pipelines; and also supports life support systems, propulsion systems, and thermal control systems to ensure the safety of astronauts and stable operation of equipment. WaFu Brothers provides reliable support for aerospace missions with advanced technology and has become an important partner in the industry.

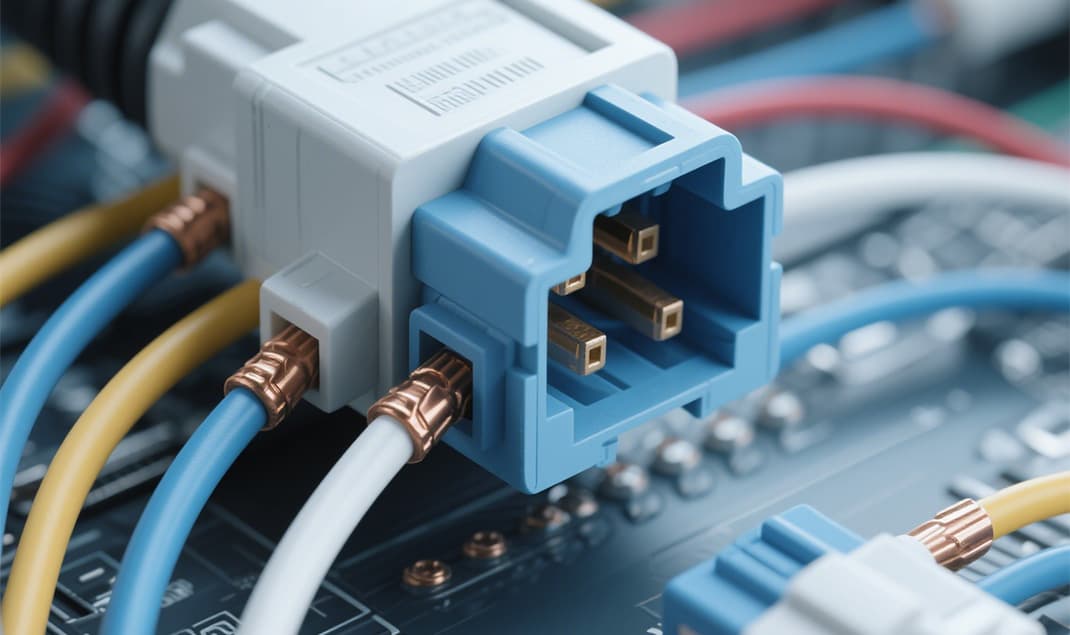

Hermetic Electrical Connectors

According to NASA statistics, approximately 15% of electronic system failures are directly related to connector seal failures, making leak testing a mandatory inspection item for aerospace-grade connector production.

More