WaFu

Brothers (Shenzhen) Automation Technology Co., Ltd. was

established in 2009. With 16 years of experience in the production of leak testers

and non-standard automation equipment, it is one of the first manufacturers of

airtight and waterproof testers in China, serving more than 8,000 customers at home

and abroad, including Audi.

We regard product quality as our life. We strictly follow the ISO9001 quality

management system in every production link of leak detectors. We regard product

innovation as our blood and attach great importance to R&D investment. Over the

years, the annual R&D investment in leak detection technology has accounted for more

than 20% of sales.

For 16 years, we have been striving to move forward. The spirit of striving for the

first place has become the belief engraved in the bones of all employees of WaFu

Brothers. The flowers that we have watered with sweat day and night for many years

have finally borne fruit. We are the first to completely solve the industry's major

problem of sealing detectors-environmental interference affects detection accuracy!

We serve our customers wholeheartedly and are deeply loved by them. Our customers are

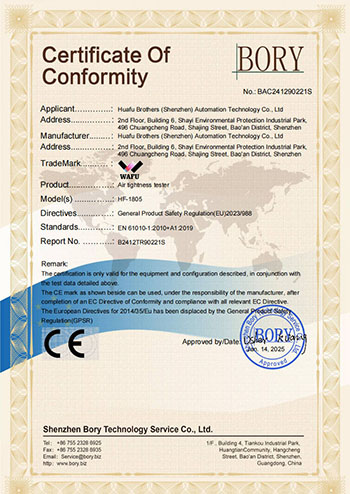

all over the world. We have obtained many domestic and foreign product patents and

numerous domestic and foreign honorary certificates. We are the first in the

industry to obtain many relevant certifications such as AAA-level credit enterprise,

Guangdong Province famous brand, Guangdong Province product quality assurance

enterprise, 3.15 key recommended brand, etc.

Looking to the future, WaFu Brothers will uphold its original intention, strive to be

the best supplier and solution provider of domestic substitution in the leakage

tester industry, and win glory for the country!