Wafu Brothers Guide You Through Leak Testers!

How to Choose the Right Leak Tester?

In today's industrial production fields, leak testers play an extremely important role in ensuring product quality and safety. To help enterprises and professionals better understand and utilize this critical equipment, Wafu Brothers provides detailed explanations on leak tester usage methods, calibration standards, operating procedures, parameter adjustment, working principles, equipment pricing, troubleshooting, and maintenance.

Working Principles

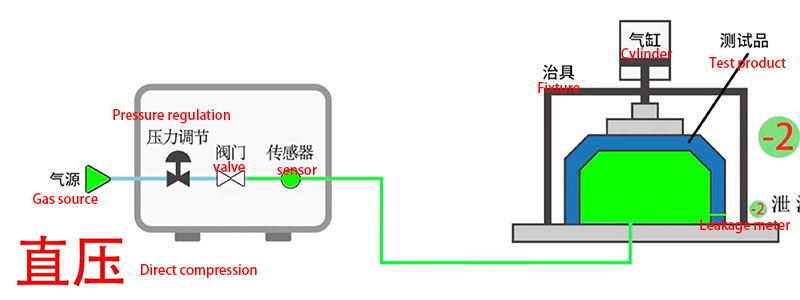

- Leak testers primarily detect product airtightness using different physical principles, including direct pressure method, differential pressure method, and flow method.

The direct pressure method works by filling

the test object with gas at a specific pressure and monitoring pressure changes

over time. If pressure changes exceed set parameters, it indicates leakage

issues. This straightforward method suits general products with moderate

precision requirements.

The direct pressure method works by filling

the test object with gas at a specific pressure and monitoring pressure changes

over time. If pressure changes exceed set parameters, it indicates leakage

issues. This straightforward method suits general products with moderate

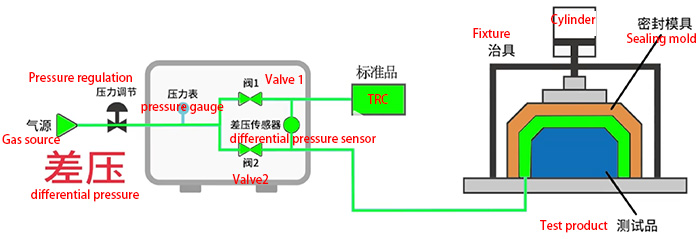

precision requirements. The differential pressure method

compares pressure differences between standard and test samples. Highly precise

and resistant to environmental interference, it's ideal for testing precision

electronic components and high-end automotive parts with strict airtightness

requirements.

The differential pressure method

compares pressure differences between standard and test samples. Highly precise

and resistant to environmental interference, it's ideal for testing precision

electronic components and high-end automotive parts with strict airtightness

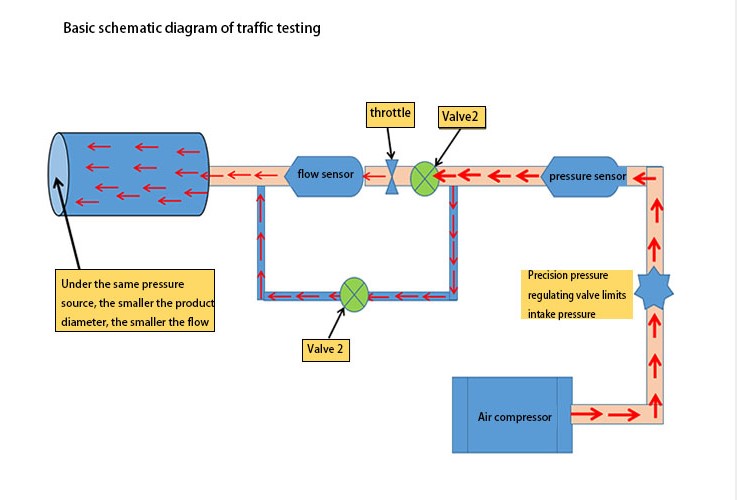

requirements. The flow method detects gas leakage by measuring flow

rate changes, particularly useful for products requiring quantitative leakage

rate analysis, such as those with micro-leakage conditions.

The flow method detects gas leakage by measuring flow

rate changes, particularly useful for products requiring quantitative leakage

rate analysis, such as those with micro-leakage conditions.

Usage Methods

When using a leak tester, first ensure stable operating conditions, proper power connection, and sufficient warm-up time. Then select appropriate fixtures based on product characteristics, ensuring proper sealing at connection points to prevent gas leakage affecting results. Next, input accurate test parameters (charging pressure, stabilization time, test duration, etc.) according to product specifications. After setup, initiate the test program. The tester will automatically charge gas and perform the test, displaying results for operators to determine product qualification.

Calibration Standards

Regular calibration by qualified metrology institutions or trained technicians is essential for maintaining accuracy. If you're considering purchasing Wafu products, please contact us for professional advice. We recommend comprehensive calibration every 6-12 months, with shorter intervals for frequent use or harsh environments. Calibration uses precision instruments like high-accuracy pressure sensors and flow calibrators to verify key parameters (pressure accuracy, resolution, flow measurement, etc.), ensuring they meet specifications within acceptable error ranges.

Operating Procedures

Operators must receive proper training on control panels, function keys, and procedures. Strictly follow established processes for product installation, parameter setting, and testing initiation. Record and store test data properly for traceability. Maintain clean working environments to prevent damage from dust or moisture.

Our newly launched Automatic Cabinet Leak

Tester significantly simplifies these processes. Operators simply place

products in the cabinet, set parameters, and the system automatically completes

airtightness testing, laser marking, and data recording. The large

display shows clear results, and manual buttons allow easy operation control.

Our tester excels not only in performance but also in design, usability, and safety

(including anti-pinch protection). It serves various industries like electronics,

automotive components, and aerospace. Custom solutions are available - contact us for professional service.

Parameter Adjustment

Proper parameter adjustment ensures accurate testing. Different products require different settings - small electronic components may need lower pressure and shorter stabilization time, while large equipment requires higher pressure and longer testing duration. Operators should combine product specifications with experience to optimize parameters (charging pressure, stabilization time, test duration, leakage threshold) through trial tests.

Pricing

Leak tester prices vary significantly. Direct pressure models (¥1,000-10,000) suit basic needs; differential pressure models (¥10,000-100,000+) offer higher precision; flow models typically cost ¥10,000-50,000. Prices also depend on brand, accuracy, testing range, and features. Premium models provide more reliable performance and better after-sales service. We offer unlimited customization - if you can conceive it reasonably, we can build it!

Troubleshooting

Common issues include abnormal result fluctuations, charging failures, or display problems. For fluctuations, first check product installation and environmental factors before examining internal sensors or circuits. Charging failures may stem from gas supply issues, pipe blockages/leaks, or valve damage. Display problems could indicate hardware or software faults requiring professional repair.

Maintenance

Proper maintenance extends equipment life. Regularly clean surfaces with soft cloths and internal components with appropriate tools (avoiding sensitive electronics). Inspect pipes for wear and perform functional checks using self-tests or standard samples to identify potential issues early.

As critical equipment for industrial production, understanding leak testers and following proper operation/maintenance procedures significantly improves product quality and reduces costs. We hope this guide helps users master this essential testing tool.

Landline: 0755-2726-7551

Customer Service (WhatsApp): +86 17376311087

Email: wafubrother@outlook.com

Recommended Products