Importance of Leak Testing for Electric Toothbrushes

As daily-use health appliances operating in humid, wet, and vibrating environments, electric toothbrushes contain motors, batteries, and control circuits. Poor sealing may cause:

| Issue | Description |

|---|---|

| Water ingress | Circuit board or battery damage from moisture |

| Safety hazards | Internal corrosion, short circuits, overheating or explosions |

| High return rates | Malfunctions and charging failures |

| IPX6/IPX7 test failures | Prevents product launch |

| Brand reputation damage | Frequent after-sales issues impact customer trust |

Therefore, precision leak testing for complete units or housing components is essential for reliable waterproof performance.

In 2022, a leading personal care brand encountered IPX7 certification failures. Investigation revealed micro-leaks in charging port seals. After implementing mass flow leak testers with ≤0.25 sccm thresholds and structural optimizations, the product passed certification and achieved mass production of 500K units/month.

Common Leak Testing Methods for Electric Toothbrushes:

| Method ID | Method | Principle | Features | Recommended Use |

|---|---|---|---|---|

| 1 | Mass Flow Method | Monitors gas flow rate under pressure | High precision for electronic products | Full inspection and quality control |

| 2 | Differential Pressure | Measures pressure decay in test chamber | Cost-effective for component screening | |

| 3 | Water Immersion (Auxiliary) | Visual bubble detection underwater | Destructive, low efficiency - R&D only |

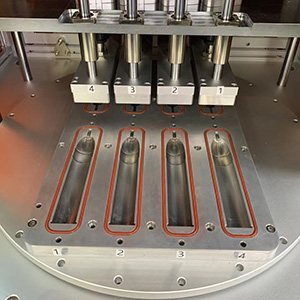

Leak Testing Procedure (Mass Flow Method Example)

| Step | Procedure |

|---|---|

| 1 | Fixture loading: Place toothbrush in custom test fixture |

| 2 | Seal formation: Close fixture to create test chamber |

| 3 | Pressurization: Inject air/nitrogen (60-120kPa typical) |

| 4 | Stabilization: Monitor leakage rate (sccm) |

| 5 | Result determination: Automatic pass/fail output |

| 6 | Data recording: MES integration for traceability |

Leak testers are essential for ensuring waterproof reliability in consumer electronics, supporting product quality and brand reputation.

Recommended Products