1. NMC/NCA Lithium-ion Batteries

NMC/NCA lithium-ion batteries use lithium nickel cobalt manganese oxide (NCM) or lithium nickel cobalt aluminum oxide (NCA) as cathode materials, offering high energy density and reactivity, but also requiring stricter safety measures. Poor sealing may lead to the following issues:

| Issue | Detailed Description |

|---|---|

| Higher fire risk | The NMC/NCA system is extremely sensitive to moisture and electrolytes. Even minor leaks can lead to thermal runaway or explosion. |

| Reduced lifespan | Inadequate sealing causes electrolyte evaporation and internal corrosion, leading to rapid capacity degradation. |

| Process instability | Production variations may cause poor welding or sealing of electrode tabs, requiring real-time monitoring of sealing quality. |

A new energy vehicle battery pack manufacturer experienced swelling and sudden capacity drops in numerous NMC battery packs due to poor cell sealing, ultimately leading to vehicle recalls costing tens of millions. The company subsequently implemented automated leak testing equipment to conduct 100% inspection of each cell and module, completely eliminating inspection oversight risks.

2. For different packaging types (prismatic, cylindrical, pouch), NMC/NCA batteries are suitable for the following leak testing methods:

| Method No. | Method Name | Detailed Description |

|---|---|---|

| 1 | Differential Pressure Method (Pressure Decay) |

Cost-effective solution suitable for medium-precision testing of prismatic or cylindrical NMC cells; Can monitor leaks in electrode tabs, filling ports, and safety valves. |

| 2 | Mass Flow Method |

High sensitivity, ideal for high-volume automated production lines; Suitable for pouch NMC batteries or high-end energy storage cells. |

| 3 | Helium Mass Spectrometry (Helium Leak Test) |

For products requiring ultra-high reliability (e.g., aerospace batteries, energy storage systems); Can detect extremely small leaks of 10⁻⁶~10⁻⁹ Pa·m³/s. |

3. Testing Procedure (Using Prismatic NMC Cells as Example)

| Step No. | Specific Procedure |

|---|---|

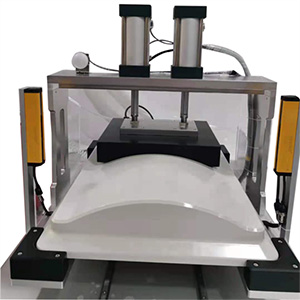

| 1 | Loading preparation: Robotic arm places prismatic cells into test chamber. |

| 2 | Chamber sealing: Close and automatically lock top cover, begin vacuum or pressurization. |

| 3 | Test pressure application: Inject dry air or nitrogen to set pressure (e.g., 300kPa). |

| 4 | Pressure stabilization: Set dwell time (e.g., 2-5 seconds) for gas stabilization. |

| 5 | Data acquisition: System automatically records pressure decay or leak flow rate. |

| 6 | Pass/fail determination: Automatic OK/NG judgment based on leak rate thresholds. |

| 7 | Result output & traceability: Upload test data to MES system for full-process traceability. |

Leak testing is a critical quality control measure for ensuring NMC/NCA battery safety, extending service life, and maintaining performance consistency, particularly crucial for new energy vehicles and high-end energy storage cell manufacturing.

Recommended Products